After completion of the breadboard stage the questions were laid to rest. After more than a year exploring the circuit variations which tugged on the curiosity the circuit wound up back at the original design with parts section as anticipated. I should add here that the "natural motion" of an interstage or output transformers spoken of in vintage tube building lexicons that does indeed sound more natural than any of the other topologies such as, Ultra Path, Parafeed, plate chokes, plate resistors, plate CCS etc... The AC activity moving in both directions simultaneously within the transformer might have something to do with it. This speaks directly to the hierarchy of circuit over layout, layout over parts.

It was time to build up the first basic unit using mostly off the shelf parts and M6 cores.

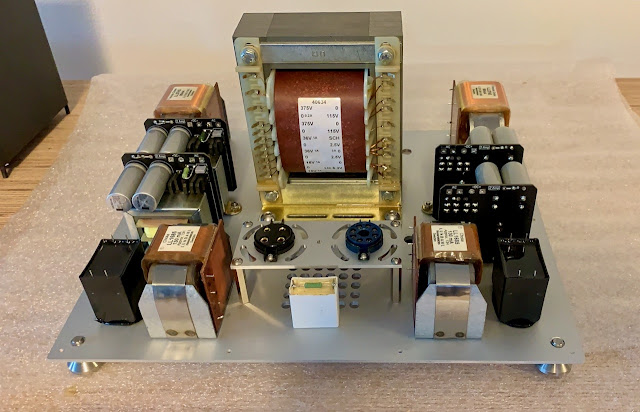

Initial layout and parts mounting.

Wiring begins with earth rails and cathode supplies...

Rear panel goes on to allow signal input wiring and power entry.

Basic model uses Chimera Labs interstage and LL2766AM Opts.

Wiring complete. 10% silver clad copper in PTFE tubing is used through out. Air is the primary dialectric inside the PTFE as it is not snug. Silver oxide will develop but the copper is hermetically isolated from the atmosphere.

Completed unit in provisional livery to get it going - final design to be published soon.

Power Supply

Since this is the heart of an amplifier it should probably be explained a little. The centre piece is the AC transformer designed for this amplifier. It has low DCR is internal shielded and drained with grain oriented electrical steel. No resistors are used to adjust voltage as they dissipate musical dynamics into heat. Four heater supplies are provided - one for each tube section. These utilise Schottky rectifiers and CMC choke loaded supplies on both positive and negative rails. B+ supplies share the AC transformer, rectifier and ground leg damper diode. The mercury vapour rectification provides not only regulation with very low resistance but also does not sag under load. The current creates a plasma bridge which increases or decreases with load maintaining the same voltage drop. The plasma's response to load also provides a very natural sounding regulation. The low DCR of the AC transformer is not compromised thus. 200H of low DCR inductance does the filtering with low ESR capacitors of high quality in an LCLC configuration for the power section. Inductance dominates the supply. This is furthered by a current source, nickel chokes and VR tube regulation to provide the driver section with clean dynamics. As good as the new Vishay DC Link caps are the long standing favourite of GE 97 and 27 series oil caps still win the day and are used at the final stage of the power section. No other oiler sounds like them.

Cover in place and a little long exposure.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.